What can you do as a lab to innovate the healthcare field?

1

Explore FabCare resources, learn and participate actively in the network

Level: newbieRead more

Whenever approaching something new, makers know they have to study first, and co-design new solutions in healthcare is not different. Luckily, a lot of material is available online and almost always for free. If you want to do activities, start from this: search for courses, summer schools, workshops during Fab Events and Maker Faires, etc. Follow more experienced labs and the FabCare network online to have an idea of the possible formats and outputs. By doing so you’ll be ready in no time to start the first hands-on activities.

FabCare toolbox and FabCare workshops at Fab16

FabCare was born with the idea to help labs all over the world to do activities with their local communities and have an impact on the healthcare world. We want to provide useful tools and peer2peer exchange opportunities to help our community to grow. If you’re interested to learn more, subscribe to our newsletter, we’ll use it to share interesting initiatives and projects done by labs around the world. In the toolbox page you can find free materials you can download to support your co-design activities. Every year, we organize workshops and meetings during the International FabEvent, check out the program for this year’s activities.

Join us to the FabCare group2

Trigger the discussion and talk about it

Level: newbieRead more

First, we need to talk. Makers, people with special needs, healthcare professionals and caregivers often don’t know each other, don’t use the same terms, don’t go to the same places. You have to give them a space where to meet. Create events, open nights, introductory courses to technologies with this objective in mind, anything can foster the cross-pollination of ideas and perspectives.

D4E1, Design for (every)one

Howest is the university behind the inspiring project D4E1- Design for (every)one and during Kortrijk Creativity Week in 2019 Howest presented an exhibition of their co-created solutions for disability and organised a discussion about open innovation and the role of fab labs/makerspaces to generate social impact.

More about the project3

Replicate existing solutions

Level: newbieRead more

Replication is, on average, more straightforward than development, and the most effective way to learn how to do something new, it is also a way to increase the impact of good ideas: if nobody makes them, they are not really impactful. During the COVID-19 pandemic we have seen the importance of replication. The Maker response helped so many healthcare professionals to get PPE, when the traditional production system didn’t manage to comply with the fast growing need.

Sometimes it is enough to find and replicate solutions developed elsewhere, both to answer to your users needs and as a way to grow confidence and gain experience.

There is a long list of platforms that have great contests to start from: some of them are entirely dedicated to healthcare and some have a specific category or tags. One hour spent searching could save you days later on!

OSMS

OSMS (Open Source Medical Supply) is a global network of over 70,000 makers, fabricators, community organizers, and medical professionals working to meet the unprecedented medical supply challenges stemming from the COVID-19 pandemic. They kept track of the medical supplies produced in 2020 and globally the number is around 48.3 million pieces! Even just replicating existing solutions have had a great impact!

More about the project Check out the platform list4

Develop new solutions

Level: proRead more

If you know people that might benefit from a custom made solution, involve them in your lab and start co-designing together.

Out there you can find a lot of nice projects, kindly shared in open source for everybody to use. Start from there! Even if it’s not perfect, you can still modify it or get inspired (always remember to credit the authors and mention the sources!). And whatever you do, remember to share your own solutions with the community! Doing so, you enable users to develop what they really need!

You can invite your users to come to the lab, or organize dedicated events such as a hackathon together with your local makers, or dedicated “FabCare nights” on a regular basis. Start small and let things take off, big gatherings require big organizations, and too ambitious projects could backfire and disappoint your users. It is better to be honest from the beginning and manage people’s expectations.

The Light Cane

The Light Cane is a luminous white cane that can signal the presence of a visually impaired person even in dark streets, increasing their safety. Debby Marchena co-designed it during Fab Lab Amsterdam monthly meetings dedicated to health and care.

More about the project5

Explore healthcare in advanced training programs

Level: proRead more

Is your lab involved in advanced training such as university courses, summer schools, Fab Academy or Fabricademy programs? That’s great! Very often it is required to develop a final project or do research on a specific topic. Use these opportunities to engage students on the topic and develop useful solutions with your user! Doing so, you’re not just having a positive impact on your community, you’re also working with a concrete need, proactive users and real feedbacks on your project.

My Orthotics

My Orthotics is Adriana Cabrera’s Fab Academy final project. It is a dynamic hand orthosis developed by using Digital Manufacturing to produce an individual and low-cost solution for hand and arm disabilities, allowing patients, therapists, and practitioners to develop this assistive device in collaborative maker spaces.

More about the project Read the scientific paper6

Bring innovative products to the market

Level: expertRead more

Sometimes small projects can go long ways. Your Lab can help young makers, designers, small startups, passionate users to do the extra mile and develop prototypes further into products.

Going to the market is a big step that might scare you, don’t let it get you down! There are many ways in doing so, for example crowdfunding platforms allow you to spread the word about your solution, increase the potential of your communication and, if successful, get funding to further develop your product.

Need help?

Send us an email at hello@fabcare.network

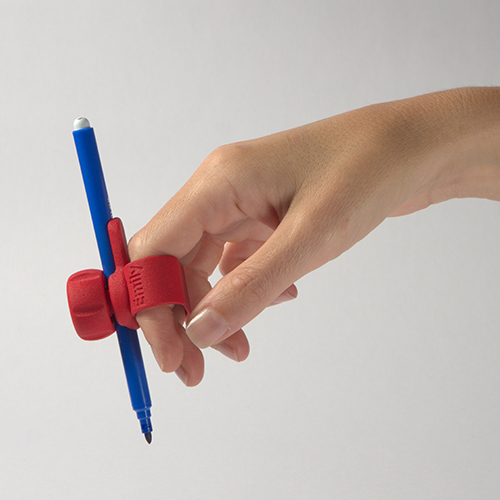

Glifo

Glifo is a small 3D printed aid, started as a student project in 2016. Since then it has been redesigned and tested twice, since it became a product in 2020. Now it is possible to order a custom made, 3D printed Glifo from an online configurator, that enables everyone to design its own one.

More about the project Try the configurator7

Teach to healthcare professionals and users

Level: expertRead more

An important step forward is to train healthcare professionals directly or technicians working with them, to give them the basics of digital fabrication technologies. It is a fundamental step towards a more proactive and independent approach to the development of new solutions. To optimize the resources and maximize the impact, it is important to define the training program together with the users and redefine every time software, hardware and objectives. Some of the contents are pretty advanced, but the most difficult aspect is to speak to your students, with a comprehensible language (being too detailed in your explanation could make things less clear) and relevant examples\exercises.

Need help?

Send us an email at hello@fabcare.network

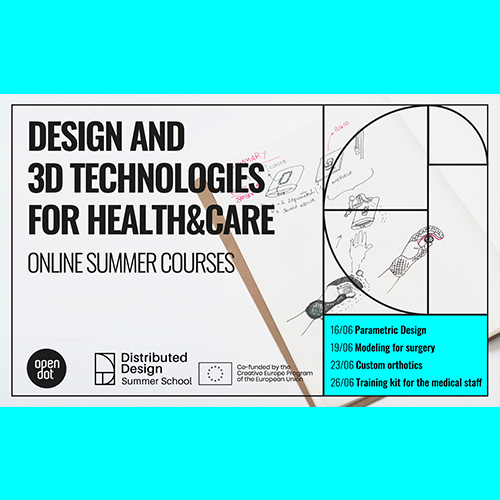

Distributed Design

Distributed Design is an international project that aims at developing and promoting the connection between designers, makers and the market. In 2020, an online summer school was organized to teach how design processes and digital fabrication technologies can innovate the healthcare field by producing effective solutions for real needs. The four lessons, available online for free, include parametric design, modeling for surgery, custom orthotics and training kits for the medical staff.

More about the project8

Co-design advanced solutions

Level: expertRead more

Some needs are very specific and particularly complex to solve. Sometimes the main obstacle is the regulatory framework, the approval process, the durability in a specific environment or the heterogeneity of the users. In these cases co-design needs to be more structured, involve more professionals and might require more advanced fabrication technologies. It is often done in cooperation with organizations such as hospitals and foundations and requires the involvement of experts and larger co-design teams. It is not the first step to take, but the projects are very rewarding!

Need help?

Send us an email at hello@fabcare.network

OpenDot

OpenDot is a Fab Lab that has been working in health and care co-designing with a need-expert partner. The projects developed include software as well as digitally fabricated products. TOP is a suite of applied games based on the eye-tracking system to support the rehabilitation of children from 3 to 12 years old with complex neurological problems co-designed together with TOG and scientific partners. Ninì’s Bag is a foldable rehabilitation aid developed together with Centro Coala, the Ospedale Buzzi’s center for children with leukodystrophies, comfortable, easy to move and able to fulfill exercises for three postures - lying, sitting, standing - according to children’s needs.

Check out TOP Check out Nini's magic purse9

Support hospitals and care centers to adopt digital fabrication

Level: expertRead more

The following step after developing solutions first hand, is to enable others to do it autonomously. This is particularly important for hospitals, rehabilitation centers, and occupational therapy labs. Engaging them is not easy and it might take a long time, but it is a crucial step in spreading the adoption of digital fabrication in health and care. Start with doctors, nurses and therapists first, they will be your ambassadors later on. The obstacles you might encounter could be: healthcare professionals' limited free time to invest on the projects, bureaucracy, internal regulation about the use of spaces and safety, etc.

Co-design in this field goes from understanding together the equipment of the internal lab, to providing personalized training. A good strategy is to identify the low hanging fruits, and start from there: customized handles, pre-surgery reproduction, 3D printed plasters, and so on. It might be fundamental to have a ROI analysis and, for private structures in particular, a business plan. These are long term projects and require experience and reliability, so approach these organizations when you feel you’re ready.

Need help?

Send us an email at hello@fabcare.network

TOG

Since 2015 TOG foundation, a center for the rehabilitation of children with cerebral palsy based in Milano (Italy), has been co-designing new customized tools meant to help the little patients with the fab lab OpenDot. Technologies like 3D printers have become part of daily workflow at TOG and this will lead to the next step of opening a fablab devoted to healthcare for therapists, doctors, caregivers, makers, people with disabilities in the new headquarters under construction in Milan.

More about the project10

Do research and international collaborations

Level: expertRead more

Digital fabrication in health and care is a relatively new field: there are a lot of aspects that would benefit from research, from the social impact of empowering the communities of people with disabilities, to the possible cost efficiency of 3D printed training tools for doctors. If your lab is interested in research as well (in particular if it is part of a university or a research center), think about writing papers, participating in conferences, applying to EU research and innovation actions. FabCare can support you in finding partners and collect data.

Need help?

Send us an email at hello@fabcare.network

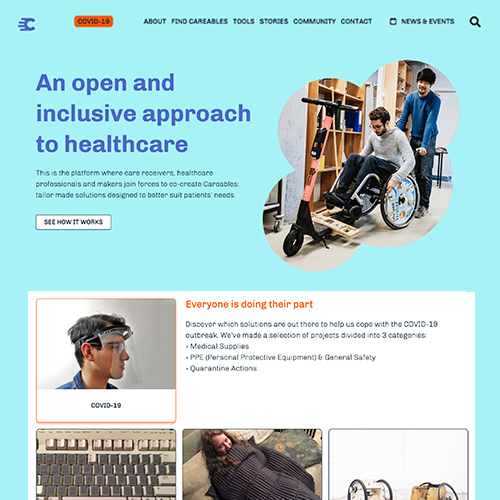

Careables.org

Careables.org is a EU funded research and innovation project that aims to involve care-receivers, care-givers, healthcare professionals and makers in the development of their own solutions. After three years it created a platform, a collection of customizable solutions, materials in support of codesign process and a community map. During COVID-19 it also helped local platforms to share solutions to the local community to support the maker response. It explored the connections between digital fabrication and healthcare in multiple ways, including research papers, conferences, and university courses.

More about the project Read the scientific paper